-

Protecting Lives for 100 Years.

By the numbers, we've developed thousands of products, own hundreds of patents and have a global reach into the millions to keep in motion our mission that began 100 years ago.

Take a few minutes to explore our milestones by decade. Select View All Events This Decade for the full list of accomplishments.

To get started, select the right arrow below.

-

1914

MSA was Founded

MORE INFO

1915

First Product Launched

MORE INFO

1917

MSA Aided in Time of War

MORE INFO

1914

First Products Created

MORE INFO

1910 — 1919 A decade of MSA in review:

1914 Metal signs in five languages were among MSA's first products sold. 1915 Sales of the Edison Cap Lamp accounted for 20% of dollar value of Edison's battery business. 1916 1000 Edison Cap Lamps and charging racks were ordered for St. Louis Rocky Mountain and Pacific Coal Company. MSA Oxygen Inhalator developed for resuscitation and aided in pneumonia patients and shock treatment. Carnegie Steel Company contracted MSA to develop an on-site safety program. The gathering of other steel companies for safety education led to the formation of Western PA Safety Council. 1917 MSA became an official corporation in Pennsylvania in January. 1918 At the conclusion of WWI, Deike and Ryan borrowed capital and purchased patents for respirator development. MSA All-Service Gas Mask began using facepiece from WWI Burrell Gas Mask until molded rubber design was developed in 1930's. MSA expanded into steel, glass, and chemicals industries, becoming a multi-faceted company committed to sales, manufacturing, education, and research in safety in a variety of settings. 1919 Patent purchased for CO catalyst used in gas masks. Hopcalite name came from joint developing institutions: Johns Hopkins and University of California. Gibbs Breathing Apparatus was sold to industries, fire departments, ocean steamships, and health departments. Deike and Ryan established graduate fellowships at Carnegie-Tech to research industrial and mine gases. MSA's second product catalog included gas masks, detectors, and even playground equipment. H-H Inhalator used a mix of 5% CO2 and 95% O2 called Carbogen known for its gentleness on the lungs.

June 14, 1914

MSA was Founded

From day one, Mine Safety Appliances has been a leader in keeping workers safe. Our mission started with founders John Ryan and George Deike on June 14, 1914 when MSA set up a workplace in downtown Pittsburgh, PA. Their first order of business was to enlist Thomas Edison to scale down his alkaline battery to power a flameless cap lamp.

1915

First Product Launched

In February, the Edison Flameless Electric Miners' Cap Lamp was the first to receive the US Bureau of Mines approval – and the first order for 500 cap lamps shipped to the Carlisle mine in West Virginia. Edison called it his most humanitarian achievement, and the most difficult. The payoff is grand, reducing mine explosions by an astounding 75% over the first 25 years.

1917

MSA Aided in Time of War

United States declared war on Germany, Austria and Hungary. MSA's breathing apparatus market was created when Deike and Ryan responded to US Army's need to equip miners tunneling under enemy lines to lay explosives. Edison provided factory, materials, and skilled workers to build 200 Gibbs breathing apparatus in 90 days.

-

1920

Our First Factory

MORE INFO

1929

MSA Nearly Triples

MORE INFO

1924

Coal Dust Reduction

MORE INFO

1927

Warning: High CO Levels

MORE INFO

1920 — 1929 A decade of MSA in review:

1921 Seventeen competitive cap lamps became available, all with heavier lead-acid batteries, but none were as durable or as effective as the Edison lamp. 1923 Ryan and engineers from the Bureau of Mines (BoM) went on a safety mission to Europe to exchange American techniques for European knowledge, only to find little safety equipment in use. 1924 The MSA All-Service Gas Mask received Bureau of Mines approval July 1. MSA reps helped to revive victims who suffered from poor ventilation in the newly opened Liberty Tunnels. Edison Cap Lamps were introduced in South African mines. BoM required daily underground dust sampling based on testing at Indianola Mine. Edison Cap Lamp was selling for $18. The National Mine Rescue Association was chartered. 1925 The first mechanized Rockdust Distributor was developed. 1926 When Ryan shared his own gas mask with an injured miner during a rescue mission at Horning mine explosion, he was overcome. Deike entered the mine and saved them both. Ryan and Deike agreed never to go underground together again. 1927 MSA paid off the debt for the construction of their factory complex at Braddock Avenue near the Homewood section of Pittsburgh. 1929 The Carbon Monoxide Eliminator Company formed. This company's work on a catalytic device to cut CO emissions from auto exhaust was doomed by the introduction of leaded gasoline. MSA Export Office in New York City opened. Momsen Lung proved successful at a depth of 350 feet. MSA's Protective Hat was introduced (Skullgard forerunner).

1920

Our First Factory

Peacetime brings corporate growth. First “main” factory built on Braddock Avenue in Pittsburgh. Primary products manufactured included gas masks, hardhats, and first aid kits.

1929

MSA Nearly Triples

During the Depression decade, MSA nearly tripled their employee count from 248 to 722 by 1938 with no layoffs.

1924

Coal Dust Reduction

MSA custom-built the Standard Rockdust Distributor for each mine application, which helped to reduce explosive coal dust in the air. It sold for $1,000 - $4,000 each.

-

1930

Radiant Heat - Outstanding Protection

MORE INFO

1930s

MSA Firsts

MORE INFO

1936

MSA Topgard® Fireman's Helmet

MORE INFO

1935

BoM Approved Dust Respirator

MORE INFO

1930 — 1939 A decade of MSA in review:

1931 The second generation of the Edison Cap Lamp (Model K) was the first three-cell battery and 40 times brighter than the original. 1932 First international partnership was established for distribution of Edison Cap lamps in England. 1933 Industrial Safety Equipment Associate (ISEA) began with John Ryan as the first President. Industrial Hygiene Foundation was established to research industrial hazards. MSA split into Mining and Industrial divisions. 1934 John Ryan Jr. graduated from Pennsylvania State College in Mining Engineering. John Ryan Sr. received an advanced degree of Engineer of Mines from Pennsylvania State College. The Military Products Department was established to adapt all possible MSA equipment to military specifications. The first large-scale cap lamp installation occurred at Kirkland Lake District, Canada. 1935 John Ryan Jr. joined MSA. Installation of Model K Cap Lamps at all Butte Mines of Anaconda Copper Mining Company was completed. 1936 John Ryan Sr. directed rescue operations during the Pittsburgh flood on March 17. John Ryan Jr. graduated from Harvard Business School. Dr. William P. Yant was appointed as the first director of MSA Research on August 31; Ryan remained head of Engineering. An agreement with Temple Velocity Power Company gave MSA exclusive rights to their patents and future developments. It took many years to make the principles into viable commercial products. 1937 On January 27, MSA Canada Ltd. was established with a head office in Montreal. Combustible Gas Alarms were used for process control. The Ear Defender ear plug was introduced; the MIlitary version was known as the V51R Ear Warden. 1938 Dieke took charge of MSA's Industrial Division. The government established Works Progress Administration (WPA) and MSA provided First Aid.

1930

Radiant Heat – Outstanding Protection

MSA's Jack Lewis developed the Skullgard® Hat for industrial workers with the new plastic "Bakelite" as the raw material; designed to withstand radiant heat loads up to 350°F.

1930s

MSA Firsts

New manufacturing plant opened in Evans City, Pa and the first international subsidiary was founded in Canada.

1936

MSA Topgard® Fireman's Helmet

Similar in construction to the industrial workers' Skullgard® Hat, the MSA Topgard® Fireman's Helmet substituted Micarta for Bakelite, the latest innovation in lightweight but strong materials.

-

1941

MSA Continued to Grow

MORE INFO

1941

MSA Met War-Time Demands

MORE INFO

1947

Demand Masks Introduced

MORE INFO

1940

MSA Traveled Abroad

MORE INFO

1940 — 1949 A decade of MSA in review:

1941 John T. Ryan died following series of strokes. The Streamlined Fireman's Helmet was introduced. Military products included Army helmet liners, Navy gas masks and damage control breathing apparatus, Air Force high-altitude oxygen masks, and Velocity Power Cutters for minesweeping. 1942 New products included the Navy Oxygen Breathing Apparatus, a modified Skullgard liner for Military helmets, and the first tank helmet. The Callery Chemical plant was purchased to produce Navy gas masks. At the height of production, over 200,000 masks were made every month. 1943 The Edison Lamp Model P3E was introduced with a back-up light in case of emergency. 1944 An off-the-shelf regulator was incorporated into the underwater escape device for D-Day tank drivers and crew. 1946 The Industrial Sales Organization reached 225 people. 1947 MSA Britain was established in Glasgow, Scotland. 1948 Callery Chemical Company was formed to consolidate chemical manufacturing into one entity. The Chemox Breathing Apparatus became the industrial version of the Navy Oxygen Rescue Apparatus. 1949 The Edison Lamp Model R4 replaced the wartime model as 90 times brighter than the original 1915 version.

1941

MSA Continued to Grow

During WWII, we had 132 major military projects and employment tripled to well over 3,000. One project involved work at Oak Ridge, TN, as part of the Manhattan Project (development of the first nuclear weapon).

1941

MSA Met War-Time Demand

The same year the Japanese bombed Pearl Harbor, MSA stepped up operations to meet war-time demands, producing 300 products for US military. This included the first chemical oxygen breathing apparatus introduced, which helped to save several aircraft carriers after Kamikaze attacks.

1947

Demand Masks Introduced

MSA Demand Masks introduced, available as Front- or Back-Type, providing Oxygen (or Air) to wearer.

-

1950s

Protective Equipment Opportunities

MORE INFO

1950

John T. Ryan Memorial Lab Opens

MORE INFO

1952

Introduced the Shockgard Hat

MORE INFO

1959

Launched Single-Lens Facepiece

MORE INFO

1950 — 1959 A decade of MSA in review:

1951 The MSA Charitable Trust was established with $60,000 “to serve the general interest of the community and the public. New products included the Dustfoe 55 Respirator, Smokescope, and UltraAire Space Filter. MSA received product orders from more than 90 countries. MSA completed the movie “You Bet Your Life” to inform firefighters about the importance of wearing Gas Masks and Breathing Apparatus to fight fires. 1952 The glass-fiber protective hat was introduced in a range of molded-in colors. The Gasfoe Respirator and the Pulmonary Ventilator for home treatment of silicosis and asthma were launched. MSA developed Vitalator to administer oxygen to athletes to help them recover more quickly from exhaustion. 1953 John Ryan Jr. succeeded George H Deike as MSA's President. A 37,000 sq. ft. facility was leased near the main plant. An 18,000 sq. ft. Callery Chemical Laboratory opened. A special Explosimeter Detector for leaded gasoline and improved Fireman's helmet were introduced. 1954 An Esmond, RI plant opened to fulfill orders for government contracts. 40 Year Anniversary The Carbon Monoxide Eliminator Corporation was liquidated. MSA's equity in Catalyst Research increased to 70%. British MSA acquired the Edison Lamp facility in Scotland. A new 100,000 sq. ft. manufacturing plant and land was purchased through MSA Finance Corporation in Esmond, RI. Growth in worldwide nuclear energy broadened MSA opportunities in this market. Substantial R&D was established for confidential Government projects. A new BoM approved Air Mask and “Danger Zone” Skullgard hat with greater impact resistance. All MSA combustible gas alarms and recorders were the first to receive agency approvals of UL and FM. Callery introduced a line of electromagnetic pumps with no moving parts to move liquid metals. “Major Medical Expense Insurance” was added to the MSA benefits package. 1955 The quarterly publication “MSA Safety Progress” was launched to dramatize safety equipment and programs. A new market for medical business was established. New products included the Dustfoe 66 Dust Respirator, Gasfoe Single-Cartridge respirator, Bantam 400 Rock Duster, and D55 MinePhone. MSA sent representation to exhibitions in Paris, France; Monterey, Mexico; Tokyo, Japan; and across Latin America. 1956 MSA de Venezuela C.A. was organized. James L. Waters, Inc. was acquired in Framingham, MA. This company made scientific instruments. Protection, Inc., was acquired in Los Angeles CA. This company performed specialized research in aircraft flight. Callery received a $38.5 million contract to produce a new plant for high energy aviation fuel. The fuel was called HiCal and was formulated after eight years of research with over 400 engineers and subcontractors. The MSA Soundscope sound analyzer was introduced, as well as a line of Aluminized Asbestos Clothing. Other products included the Fixt-Flo Sampler for continuous air sampling in pollution studies, a fire-resistant Ultra Aire Space Filter, and a fire truck for mines. MSA arranged with 3M to handle the national promotion of Scotchlite Brand Reflectorized Safety Signs. A new pilot's helmet with integrated visor became the standard gear for Navy Jet pilots. MSA's Permissible Mine Lighting System was the first to receive the Bureau of Mines approval. 1957 MSAR developed a special oxygen candle that allowed submarines to remain submerged for 61 days and to go under the North Pole. Temple Velocity Equipment Company was acquired. Callery sold 25% of unissued stock to Gulf Oil. MSA Research Corporation (organized to retain all assets of Callery Division, except high energy fuels) began conducting fundamental rather than applied research. MSA established the Technical Products Manufacturing Division. Callery established a “Solid Fuel Group” to produce new solid high energy fuel for use in super-efficient rocket engines from Thiokol. A NaK liquid metal alloy was developed for heat transfer systems and chemical processing applications. Launched products included the MSA Portable Oxygen Indicator, MSA Particle Size Analyzer and MSA Explosilarm, and Colorimetric Detector Tubes for various toxic gases. A breakthrough E13 Protective Mask for Chemical Warfare Service eliminated canister and protected against atomic, biological and chemical warfare. 1958 Gulf Oil acquired 50% of Callery. New products included the Fixed-crown hardhat suspension; Window-Cator Canister for All-Service Gas Mask, and Noisefoe Mark II muff with cooperation from Radio Corporation of America (RCA). A new line of filters included “Ultra”-type capable of maintaining sterile air in operating rooms. A MSA Spacehelmet was designated as head protection for world's first man to travel more than 100 miles above earth. The Blue Angels and U.S. Navy adopted MSA's Aviator Crash Helmet as the standard issue. MSA investigated the method of converting thermal energy to electrical energy (fuel cell) and presented it to professional societies. Callery pioneered the production of HiCal, high energy fuel for the US Navy Project Zip. 1959 The Carbisulphoil Company in Dallas, TX was acquired. The Navy cancelled its high-energy fuel contract with Callery Chemical due to a shift from high-speed aircraft to missiles. MSAR built a life support system that could sustain seven men in a simulated 14-day space trip. New products included Thru-Steel Dust Collectors for rotary drilling, New Auer protective hat, a one-piece lens Clearvue facepiece for virtually the entire line of breathing apparatus and gas masks as well as a low-cost LIRA Analyzer. MSA received a $3 Million order for M17 Gas Mask from the US Army Chemical Corps. The Model S Edison Cap Lamp launched. Developed for Project Mercury, MSA introduced systems to remove CO2 from air.

1950s

Protective Equipment Opportunities

Post WW II expansion in cutting-edge areas of nuclear energy and the space program provided new opportunities for protective equipment.

1950

John T. Ryan Memorial Lab Opens

John T. Ryan Memorial Lab opened in Pittsburgh on June 14, 1950, with over 400 people in attendance. This was the largest facility devoted exclusively to the research and development of personal protective equipment and worker and plant safety. It also contained the largest library in the world devoted to safety.

1952

Introduced the Shockgard Hat

Shockgard hat for electrical linemen introduced to protect against electrical shock up to 10,000 volts.

-

1969

MSA in Space

MORE INFO

1961

New Helmets Introduced

MORE INFO

1960s

Gas Masks for the military

MORE INFO

1960s

International Rapidly Expanded

MORE INFO

1960 — 1969 A decade of MSA in review:

1960 A Portable Defibrillator was developed in conjunction with Johns Hopkins University and Edison Electric Institute to counter-shock heart attacks. Protection, Inc. Division was sold, which developed protective gear for military aviators. MSA received a $9 million contract by the US Air Force for Pentaborane. A new line of Sightgard Safety Eyewear was introduced at the National Safety Council (NSC). The first half-hour ChemOx apparatus launched. MSA Rescue Communication System provided conference communication between the base headquarters and rescue workers. An Individual Atmosphere Control Unit was developed to provide two-hours of oxygen supply by regenerating air inside a pressure suit. Research investment is four times greater than it was in 1950. A pilot plant was built to produce high purity cesium and rubidium for use as coolant and ion propulsion. ChemOx OBA was successfully used in combatting a fire aboard aircraft carrier Constellation at the Brooklyn Navy Yard. 1961 The B. F. McDonald plant in Los Angeles closed. MSA de France Société à responsabilité limitée was formed. Foamaker was introduced for fire suppression. A New Industrial Gas Mask was introduced with Clearvue Facepiece. New Custom Comfo Respirator was launched. An Improved Oxygen Candle (for OBAs) was launched, delivering 40% more oxygen than previous models. A CBR Filter was released in two sizes for protection against chemical, biological, radiological warfare agents. The smaller version was for family shelter use, and the larger version for industrial or group shelters. 1962 MSA Australia was organized. V-Gard® Helmet was launched. Rigiseal, a rapidly expanding, quick-setting urethane foam and spray-gun system for temporary or permanent stoppings was introduced. Distillation Chromatograph for oil refineries permitted a single instrument to monitor the complete boiling range of many petroleum products. MSA field-tested a Sonic Pinpointer for gas leaks. The sterilization air-filtering system for Project Apollo removed all but one of every 10 quadrillion particles as small as 0.3 micron. An auto seatbelt promotion extends on-the-job safety to off-the-job activities. 1963 William Parks Yant, MSA's first Director of Research, passed away on January 29. George H. Deike Sr. passed away on July 16. Eugene W. Merry was named the Executive Vice President. MSA awarded its first $1,000 scholarship The MineSpot lighting system was introduced. The Billion-Aire analyzer was reduced to a portable model. It was able to detect over 50 toxic gases in the parts per billion range. A Rocket Fuel Handler's mask was developed for Strategic Air Command. 1964 MSA celebrated its 50 year anniversary. Catalyst Research acquires 74% Electronic Aids, Inc. a pioneer in comprehensive electronics courses for Junior High thru Junior College. Callery Chemical produced 99.99% pure potassium, cesium, and rubidium for use in advanced nuclear power generation and ion propulsion. MSA Pressure Demand Air Mask introduced. Pressure demand means that there is a higher air-pressure inside the mask than the surrounding atmosphere, to prevent bad outside air from seeping in where it could harm the wearer. A Prototype Methane Monitor was introduced for miners. MSA Model 550 Chromatograph Analyzer was launched at the Instrument Show. The Monitaire Sampler personal sampling pump was introduced. A Personal Air-Conditioning System was launched, which combined Cool-Flo Vortex tube with protective clothing. THERM-O-BACK insulating foam was introduced for use on aluminum siding. 1965 MSA re-acquired its half-ownership of Callery Chemical Company held by Gulf Oil Corp. A 60,000 sq. ft. facility in Allison Park opened with a Molded Specialties Department for plastic parts. This facility doubled MSA's hat manufacturing capacity. MSA's commercial sales exceeded government sales for the first time. MSA sponsored the first Yant Memorial Award on behalf of AIHA. The award was presented to Henry L. Green, former Deputy Chief Scientific Officer of the British Scientific Civil Service. A Cut and Sew Department was established to produce safety clothing. The cost reduction of OBA Canisters was named as one of top five outstanding examples of effective supplier value in Defense Secretary McNamara's report to President Johnson. 1966 Mine Safety Appliances Limited was established in Calcutta, India. MSA Espanola was established in Barcelona, Spain, of which 75% was MSA owned. MSA Far East Limited was established in Tokyo, Japan. Gene Merry was elected President and COO. John Ryan Jr. was elected as Chairman and CEO. The scholarship program expanded to one for hourly and one for salaried employees’ children. It was renamed in honor of George H. Deike. MSA received a $28 million contract for M17-A protective masks. MSAR was active in liquid metal heat transfer systems for the Breeder Reactor program. The Model 802 Oxygen Analyzer was developed. A lightweight ballistic military helmet was created for the U.S. Army Natick Lab. Emergency breathing equipment was produced for the undersea vehicle, Trieste II. A system was built to automatically supply oxygen for a year from a solid source to a hydrogen-oxygen fuel cell. Oxygen Candle Systems were created that could generate emergency standby air for sudden decompression in passenger aircrafts. 1967 Twenty-eight new products, including Model 401 Demand SCBA, were developed in 1967. MSA del Peru S.A was established in Lima, Peru. MSA Nederland was established in N.V., Amsterdam. The Deike Building at Pennsylvania State University, named in honor of lifetime Penn State supporter and Trustee George H. Deike, Sr., was dedicated. Auergesellschaft, the company MSA acquired in Germany, celebrated 75 years. A new brand logo was introduced. Improved versions of products were developed of the MineSpot Cap Lamp, Softframe Goggles, Ultra-HEPA Filter, and Dustfoe 35 Space Filter. 1968 Callery Chemical merged with MSA in a three-for-one stock split. A National Sales Meeting was held in January. The “Make sure / check MSA” ad campaign went live. MSA developed the “On Top of the Pros” movie with Johnny Unitas to communicate the importance of head protection. MSA was featured in TV spot for Foille burn treatment. A Containment Package was developed to control the release of radioactive particles at a nuclear power plant. LIRA Analyzer Systems were used to test air around Los Angeles for CO and automobile pollution. The Police Riot Helmet and Ear and neck protector for firefighter helmets were introduced. 1969 Consolidated Sales topped $100 million for the first time at $102,443,419. This was up 26% over 1968. MSA Sao Paulo Brazil was established. MSA began a joint venture with Hokushin Limited in Tokyo, Japan. MSA operated in 17 countries and sold in an additional 80 countries. John Ryan III joined MSA. New Federal Regulations began to impact business. Auergesellschaft (referred to as Auer) introduced a monocular facepiece and Audox chemical oxygen breathing apparatus for volunteer fire departments. A Scobea emergency breathing apparatus was introduced for escaping from aircraft carrier fires. The Comfo Cap and new models of high expansion foam generators were developed for fire protection. Other new products included the 650 Chromatograph, 900 Water Vapor Recorder, and Gravimetric Dust Sampler.

1969

MSA in Space

A year known in the United States for landing on the moon, MSA designed filter system for Apollo moon spacecraft. Upon return from the moon, Apollo 12 Astronauts wore Custom Comfo® Aerosol Filter Respirators with inhalation and exhalation valves reversed so the astronauts' exhaled air was filtered to trap any potential "space microbes."

1961

New Helmets Introduced

In 1961, the Topgard® Helmet was introduced, which was the first polycarbonate hardhat. Polycarbonate is an extremely durable plastic that is very difficult to crack or break. A year later in 1962, the V-Gard® Helmet launched. Today, both helmets are part of the family of “best-selling helmets.”

1960s

Gas Masks for the military

MSA produces military gas masks for United States forces in Vietnam.

-

1976

MSA Lessens Firefighter Load

MORE INFO

1979

MSA Responded to Disaster

MORE INFO

1971

Pacemakers Powered by MSA

MORE INFO

1978

IDLH Mask Kept Bad Air Out

MORE INFO

1970 — 1979 A decade of MSA in review:

1971 A Carbon Monoxide Analyzer System was sold to EPA to measure CO concentration in various parts of country. A long-life, lithium-iodine pacemaker battery was developed by CRC. 1972 George H. Deike Jr. retired after 40 years of service. MSA “Mini-Seminars” became available to instruct PPE and small businesses about workplace hazards in order to meet new OSHA requirements. MSA's headquarters moved to Penn Center from Braddock Avenue. 1973 MSA Europe was established in Berlin, Germany. A comprehensive coal mine methane detection system was introduced. Filter packages for nuclear power plants grew new business. 1974 The shortage of petroleum for plastic precipitated MSA International's backorders in 14 countries. R&E efforts focused on conforming products to government regulations. 1975 MSA de Chile Ltda. was established. New products included the Tankscope portable Gas Analyzer, the Low-Flow Sampling Pump, and the Vinyl Chloride Gas Mask Canister. More than 130 products were submitted for certification to new NIOSH standards. 1976 MSA's headquarters took possession of an entire building on the campus of Penn Center, Monroeville, PA. MSA's manufacturing plant moved to a facility in Murrysville, PA, that is still occupied today. A new oxygen-generating self-rescuer replaced filter-type devices for underground mine rescues. The multi-year effort to meet NIOSH certifications was now mostly complete, and MSA renewed its focus on new product development. 1977 John T. Ryan Jr. retired as President but remained as Chairman of the Board. Eugene W. Merry was named President and CEO. Employees totaled over 6,000 worldwide and sales topped $200 million. Callery Chemical was contracted to produce the catalyst for solid propellant for the Viper anti-tank missile. 1978 MSA SE Asia Pte. Ltd. was established. Eugene Merry retired after 42 years. M. G. “Skip” Hulme Jr. was elected President and CEO. John Ryan III was named Vice President. New products included the Pager III communication system, the Gascope Indicator, the MiniCO detector, the 60-minute SCSR, the Model 401 Pressure-Demand Air Mask, and the New Catalyst button-cell battery. 1979 The Jacksonville, NC plant opened. An Emergency Response Program was established to stockpile respirators and other equipment that could be shipped at a moment's notice to a disaster scene.

1976

MSA Lessens Firefighter Load

Fiberglass-wrapped SCBA cylinders were introduced that significantly reduced the weight firefighters had to carry.

1979

MSA Responded to Disaster

MSA supplied respirators, filters, and room-sized High-Efficiency Particulate Air (HEPA) scrubbers from locations as far away as Washington State to assist with the Three Mile Island clean-up. Four 20-ton such units were flown in by Air Force Transport.

1971

Pacemakers Powered by MSA

In 1971, a long-life, lithium-iodine pacemaker battery was developed by MSA subsidiary CRC to power the first heart pace-makers.

-

1987

Introduction of Quick-Fill

MORE INFO

1983

Three “Firsts” for SCBA Products

MORE INFO

1986

Standard Issue Military Gas Mask

MORE INFO

1987

New Venture in China

MORE INFO

1980 — 1989 A decade of MSA in review:

1980 Ultralite fiberglass-wound air-cylinders were developed for firefighting. The Multiphone™ mine communication system was introduced. The C-210 Personal Sampling Pump launched. MSA introduced cabin air filters for Boeing 757 and 767. ETO Gas Masks were introduced. John Ryan III was elected to the Board of Directors. 1981 The Fixt-Flow® Personal Sampling Pump was introduced. The VaporGard™ Inorganic Vapor Dosimeter Tubes launched, providing unique on-the-spot test results. The Model 3000 LIRA® Infrared Gas Analyzer was developed, as well as the latest generation of MinePhone and MultiPhone Communications devices. New Small and Large Ultravue® Facepieces joined similar Comfo products. MSA introduced a Nuclear Industry Specialist position. MSA's first robot was installed in the hat manufacturing line. 1982 MSA (Switzerland) Limited was established. MSA US facilities included seven Regional Repair and Service Centers, 20 warehouses, and 120 sales representatives. A toll-free telephone line was initiated in the US. 1983 AB Tegma was acquired. MSA Hokushin Limited was divested in Tokyo, Japan. The Catalyst Research subsidiary merged into MSA. The MSA Research Division developed foam systems to fight fires and control vapors from chemical spills. Three hundred and twenty-six acres were purchased in Cranberry Township, PA in August. Computer Aided Design (CAD) sped up development of instruments and respirators. The $1 million Nuclear Emergency Stock Program was developed as a product ready for emergency use. The Comfo Hood Select-A-System was developed for the nuclear industry. MSA introduced Chempruf suits with unique air-line capability. A SSR-UW Underwater Self-Rescuer was developed for military vehicle crossings. Other new products included the Dustfoe 88, Mouthpiece and Back-Mounted Respirators, the Brigade Firefighter Helmet, and the Minigard II Gas Detector. New systems introduced included the DAN 6000/6100 Data Acquisition Network plant/mine monitoring systems as well as the MARS fully automated mine-wide rockdust distribution system. 1984 MSA broke ground in Cranberry Township for the Instrument Division building. MSA acquired land in O'Hara Township, PA for a new World Headquarters at RIDC Park. George H. Deike Jr. passed away. MSA received a large order for two DAN 6100 systems by the Ministry of Coal Industry, People's Republic of China. MSA facilities included 24 district and branch offices as well as 9 service and repair centers. The MineSpot Cap Lamp was introduced with a maintenance-free battery. A gas mask canister was developed for nuclear applications, allowing use of an air-purifying respirator instead of supplied-air. MSA's ETO gas mask was the only approved product for sterilization agents. The MiniCO V was developed with dosimeter functions. Models 360 and 361 of tri-gas monitors were introduced. The “First Team” Fire Service branding program launched. The Chempruf II Suit launched. 1985 The 200,000 sq. ft Instrument Division facility in Cranberry Township opened and the Braddock Avenue manufacturing facility finally ceased. MSA Middle East was established. Milton “Skip” Hulme passed away. MSA reduced the workforce to 7,000 employees worldwide. MSA officially had 23 international affiliates. MSA had the fourth two-for-one stock split since 1968. The Rig-Gard™ H2S indicator was introduced for oil rigs. The Tankgard™ Underground Vapor Monitor was developed for storage tanks. Other products launched included the low cost Model 3100 Infrared Analyzer, low-profile Type S respirator for use under welding helmets, a total encapsulating suit that incorporated dual-purpose SCBA, and a less expensive DAN System. 1986 MSA erected the 70,000 sq. ft. John T. Ryan Memorial Laboratory. MSA Ryan Lab relocated in March from the Braddock Avenue location. John Ryan III was elected Executive VP. L. N. Short became President and CEO. MSA further reduced its workforce to 6,400 employees worldwide. New Service Centers in Atlanta and Pittsburgh brought the total to 11. New buildings opened for MSA facilities in Germany and Spain. Additionally, MSA products were now being sold in 123 countries. MSA received 31 NIOSH approvals for respirators. Joe Bigler chaired the NFPA Technical Subcommittee for the new SCBA standard (1981). An automated document control/retrieval system was installed. A Flame and Heat Resistant (FHR) harness for SCBA was developed. The MCU-2/P military gas mask was introduced. The 30/100 minute Auergesselschaft self-rescuer for miners launched. MSA crafted the silicone facepiece and cradle headband for Comfo II Respirators. Other new products included the Flow-Lite Sampling Pump, a catalyst battery for computer back-up, and the MiniOX 100 Pulse Oximeter that could successfully measure O2 without breaking the skin. 1987 MSA opened a new 150,000 sq. ft. world headquarters in Pittsburgh, PA. A joint venture started with WUXI-MSA in China. The US salaried and hourly work force was reduced by 20% through early retirement packages. A five-year facility improvement plan began, costing $145 million. At IAFC, MSA introduced the Ultralite II and Custom 4500 II, which were the first breathing apparatus to meet new, more stringent NFPA fire service standards. The revolutionary Quick-Fill® System launched, allowing firefighters to replenish air supplies during emergencies. New products included the ClearCom® RI communications system, Series 5000 Gas Monitoring Systems, TriGard™ Gas Detector, Chillgard™ Refrigerant Leak Detection System, MicroGard™ Portable Alarm, HazMat Response Detector Tube Kit, Miniox® -IV portable oximeter added to CRC line, and a multi-year contract for M-17 A-2 Gas Masks. 1988 The lightest and brightest Ultralite® Cap Lamp yet launched, providing three times the light of conventional cap lamps. The Thermalgard cap, nylon welding helmet, and spectacles were introduced. MSA was contracted by the US military to produce a new M-40 Army Mask, MCU-2/P Air Force-Navy Mask, and C-2 Filter Canisters, and develop new breathing apparatus for the US Navy. New products included the OptimAir 6 PAPR, the Breathing Air Distribution System, and the Kwik-Draw Pump. The Chempruf II Total Encapsulating Suit began to be worn during cleanups of chemical spills when a flash-resistant oversuit, cooling system, and vest were added. The Tank-Check Leak Detection Kit was made up of the Kwik-Draw Pump and select Detector Tubes. Auergesselschaft launched the Tristar Helmet-Mask, which integrated head and respiratory protection for firefighters. An improved version of the Vautex Total Encapsulating Suit met new German fire brigade standards. British workers in Chunnel construction used V-Gard Caps and filter self-rescuers. Catalyst Research introduced the Series 9000 Heart Pacemaker Battery. Worldwide, MSA officially had the largest direct salesforce in the safety product industry, with products shipping to 120+ countries. 1989 MSA celebrated its 75th anniversary and donated its former “Main Plant” on Braddock Avenue to the University of Pittsburgh and a community organization. Thermal Battery Operations and its assets were sold. The WUXI-MSA plant began production of gas detection equipment. Product launches included: Comfo Elite Respirator; OptimAir MM PAPR, Suitable-Aire Respirator, Hip-Air Dual-Supply Breathing Apparatus, Quad-Aire Compressor, Super-Gard II and Sightgard II Faceshield Assemblies, Model 6000 Field Data Station (Part of DAN System), Lira 3250 Infrared Gas Monitor, Mini 2000 Series of Gas Monitors (MiniCO 2000, Mini H2S 2000, MiniOX 2000), Quiet-Flow Area Sampler, Tankgard VIII Leak Detection System, MiniCAP 100 CO2 Monitor for patient breath analysis. Callery conducting research into chemicals to be used in drug production for Alzheimer's, high-cholesterol, arthritis.

1987

Introduction of Quick-Fill

Developed by CEO, Bill Lambert, the introduction of the truly revolutionary Quick-Fill® System allowed firefighters to replenish air supplies during emergencies. It is now part of every firefighting self-contained breathing apparatus (SCBA), regardless of manufacturer.

1983

Three “Firsts” for SCBA Products

MSA broke ground with three new “firsts”:

- • Custom 4500 Air Mask – The first high-pressure SCBA with options in both 30- or 60-minute cylinders.

- • Ultralite® Air Mask – The lightest 30-minute SCBA.

- • Composite II air-cylinder – The lightest weight cylinders introduced to help firefighters manage the overall weight carried.

1986

Standard Issue Military Gas Mask

The innovative MCU-2/P Military Gas Mask was designed with a flexible urethane lens and extremely comfortable face seal based on measurements of over 5,000 faces. This standard issue equipment was distributed and used in the US Navy and Air Force.

-

1990s

Lost-Time Injury

MORE INFO

1995

10 to 1 Gas Hazards

MORE INFO

1994

Thermal Imaging Cameras

MORE INFO

1998

Safety Works Consumer Products

MORE INFO

1990 — 1999 A decade of MSA in review:

1990 Ultralite MMR and Custom 4500 MMR Air Masks were created, MSA's first SCBA with Mask-Mounted Regulator. The Composite III Cylinder was created and could pressurize to 3000 psig. First Team II Suit complied with NFPA standard for HazMat Responders (Blue Max inner suit with aluminized oversuit). Core-Control whole body cooling system was created for use inside total encapsulating suits and special application inside "Character" costumes at theme parks and sports facilities. Other products that launched included MiniCap III CO2 Detector, Auer S-15 OBA, Photon Gas Detector, and SupaRule Meters use ultrasonic waves to measure height of high-voltage power lines. 1991 Acquired Baseline Industries in Lyons, CO. The following products launched: Passport Personal Alarm, the smallest and lightest 5-Gas, Vari-Clear Personal Communication System amplifier and two-way radio interface for firefighters, Lifegard 5- or 10-minute Air Escape Respirator (MSA Australia), OptiFilter Combination Chemical PAPR Cartridges, Auer BD88 AE SCBA, GasCorder Portable Toxic Gas and Vapor Monitor from Baseline, Gemini Twin-Port Sampler for Detector Tubes, Gascope Combustible Gas Indicators Models 60 and 62; and HiLo hearing Protectors (MSA Britain). 1992 Auergessellschaft GmbH celebrated 100 years (Oct 5). MSA-Auer Safety Technology established in Hungary. Owings Mills (Catalyst Research) operations was closed. There was a substantial manufacturing reduction at Evans City. The Advantage 100 low-maintenance respirator launched. MSA was only manufacturer to have SCBA certified to NFPA 1981, 1992 Edition available when standard goes into effect. The following products launched: Quad Gas Monitor, PremAire Air-Line Respiratory System with connection block for customizable configurations, Portal-Pack SCSR – lightest 60-minute self-rescuer, ESP Communications System for enhanced APR facepiece speech, SSR 16N SCSR for oil platforms in North Sea, Escort Personal Sampling Pump, Chillgard IR Leak Detection System, Auer ACO2 smallest lightest hand-held CO2 indicator, Firefly PASS System, and Auto-Change 2000 Welding Lens, and the Fire/Police Mask/Helmet combination. 1993 MSA acquires HAZCO Services, Inc. to better compete in the instrument rental and repair market. MSA factories become certified to ISO-9000. Passport Alarm named first “Product of the Year.” Hardhat Logo Express was implemented; ATOs for SCBA Advantage 1000, industry's first low-maintenance full-facepiece respirator was launched. Firefly II was first PASS alarm to meet new standards. The Cobra Powered Helmet, a head/eye/face/respiratory protection in one unit launched in MSA Britain. The following products launched: Synergy Bubble Hood Respirator for nuclear personnel, WorkMask II SCBA, Cricket Personal Alarm (Single-Gas), Escort ELF Sampling Pump, TOX-Meter PID from Auer can detect trace amounts of toxic gas from 0 – 2000 ppm, and the Vanguard Helmet for lateral protection. 1994 Customer Service Center opened as a test for functionality and capability. Multi-step new product development process used detailed design reviews to maximize robust designs and minimize manufacturing problems. The following launched: Ultra Elite Facepiece and Comfo Classic Respirator, Advantage 100 Respirator for Healthcare, Response® Respirator Selector, Argus TIC; ESP Communications System for pressure demand full-facepieces, Core-Control Cooling Vest, HotSpotter Thermal Detector, Gasport Gas Detector for gas utilities, Passport PID Organic Vapor Monitor, Mini Series Single-Gas Detectors, Model 3630 and 3800 Infrared Monitors for HVAC and Oil/Gas markets, and Private Label for Trane Refrigerant Monitor. MSA Canada receives Award of Excellence from Bell Canada for Passport Portable Alarm. 1995 Sibertech participated in a joint venture in Russia with Institute of Design Engineering to make Gas Chromatographs. MSA acquired Aritron Instrument A.G. - PAIR gas sensors. John Ryan Jr, responsible for MSA's global expansion in second half of century, passed in July. Customer Service Center was deployed at Headquarters. Joe Bigler was named Director of Sales. The following launched: First Team MiniCO Response Kit for fast in-home CO testing, LowRider® HEPA filter cartridges, ShortStack small format Combination Cartridges, GME Super Cartridges approved for 10 specific gases and vapors, GME-H most widely approved cartridge available, BD 96 and Auer Air Elite SCBAs, Auer DF-8501 System to detect gas emissions in flow and smolder fires, Watchman Multigas Monitor, Auer Tox-Meter PID and Ex Meter II for combustible Gas, and the Ultima Gas Monitor remote sensor/transmitter. 1996 MSA appointed new management team, emphasized unification strategy for worldwide operations. Tom Hotopp elected President; Bill Lambert named General Manager of the Safety Products Division. Gen II ARGUS thermal imaging camera is introduced. The following products launched: Advantage 200 Respirator, Affinity line of maintenance-free respirators, MiniCO Responder for fire service, Passport FiveStar Personal Alarm (smallest five-gas detector), and the LifeSaver 60 SCSR. 1997 Esmond, RI, facility closed; work moved to Evans City plant. Global computer system launched to link all MSA enterprises electronically. 1998 HAZCO and Baseline Industries divested. MSA became majority owner of Wuxi-MSA in China. MSA Safety Works consumer product line launched. Sales completed transition to 100% indirect selling. Implemented SAP as enterprise-wide software. CSC was recognized for call center excellence. 1999 ISIG Group, TIC manufacturer, was acquired. MSA Safety Works earned Partner of the Year Award from The Home Depot. CSC earned Zenith award from TeleProfessional magazine. Third generation Argus TIC launched. Toronto Fire Service, the fifth largest fire department in North America, chose MSA for SCBA. MMR Xtreme SCBA brought new levels of performance to the Fire Service.

1990s

Lost-Time Injury

At the beginning of the ‘90s, the United States private industry reported 3.9 lost workdays per 100 fulltime workers due to injury. The rate rose to high of 8.3 by 1993. MSA continued to innovate new safety products and, by 1998, contributed to decreased injury statistics. The number of lost workdays per 100 fulltime workers due to injury decreased to 2.9.

1995

10 to 1 Gas Hazards

Respirator cartridges were originally developed to protect against a specific gas hazard or gas classification/group. If a plant had areas where multiple gas hazards existed, workers would need a different cartridge for each hazard. MSA launched the widely approved GME Super Cartridge which was approved for 10 specific gases and vapors. This cartridge protected workers against multiple hazards and allowed them to move more freely from one place to another within the plant without having to change respirators or cartridges.

1994

Thermal Imaging Cameras

MSA brings thermal imaging cameras to the fire service as the exclusive distributor for three generations of the Argus Thermal Imaging Camera.

-

2000

Ding, Ding, Ding – MSA Hit the Stock Exchange

MORE INFO

2001

9/11

MORE INFO

2000

FDNY Selected the Evolution 4000® TIC

MORE INFO

2004

FireHawk® Air Mask

MORE INFO

2000 — 2009 A decade of MSA in review:

2000 MSA acquires CairnsHelmets with over 160 years of innovative manufacturing experience, along with the most popular line of fire helmets. MSA stock began trading on the American Stock Exchange and by mid-year, experienced a 3-for-1 stock split. Evolution 4000 TIC was introduced with largest, highest resolution screen and innovative design for ease of use; it was selected by FDNY after extensive evaluation. Orion Multigas Detector launched as global product. IndustryWeek magazine recognizes Murrysville plant as one of the 10 best plants in North America. Safety Bug program wins PR Society's highest award. Callery Chemical's largest market was Pharmaceutical. 2001 Fireslayer of the Year Award was launched at FDIC. Chicago FD decided to proceed with city-wide rollout of new SCBA as planned on September 11. Pulsar Single-Gas detector launched. 2002 Bill Lambert was appointed President of MSA North America. For fourth consecutive time, FireHawk® Air Mask was the first unit certified to new NFPA standard which now includes a CBRN component and a Quick-Fill fitting requirement for all SCBA, regardless of manufacturer. MSA acquired CGF Gallet and with it the ACH helmet which received a Best Product award from US Army. Next generation Evolution 5000 TIC launched. 2003 Sales and Income rose 23% and 57%, respectively, over 2002 levels. Callery Chemical Division was sold to BASF Corporation. The number of countries with MSA operations exceeds 30. Solaris Multigas detector was developed under 10 months. Cairns 880 Tradition fire helmet launched, it was 48% smaller and 20% less expensive than competition. Adapted from MSA Australia design, Advance hardhat with cooling vents saved 10% weight and 31% cost. MSA recognized by the Newcomen Society of United States for outstanding business achievement. 2004 Sales and Income rose 22% and 41% over 2003 levels. MSA was listed on New York Stock Exchange; John Ryan rings opening bell on first trading day on July 12. MSA acquired Sordin AB hearing protection company. Millennium CBRN Gas Mask receives first approval to new NIOSH standard; the Ultra Elite Mask was added later. Bulk export license was granted to sell Evolution® TIC in Europe. The integrated Rescue belt launched, which allowed emergency egress from upper floors. Next generation TechnaCurv full-body harness launched. Sirius® Multigas Detector with photoionization technology launched. SafeSite System and HazMatCAD detectors sampled for Chemical Warfare Agents and certain toxic industrial compounds. SafeSite system was used in Times Square on New Year’s Eve, and also at the Kentucky Derby, Summer Olympics, and other high-profile venues to monitor for possible chemical attacks. 2005 MSA acquired Micro-Sensor Systems, developer of surface acoustic wave technology in SafeSite System. Gene Merry, retired President and CEO and key leader and major contributor for nearly 70 years, passed. The next generation of the Evolution 5200 TIC launched with enhanced image quality and hi-res picture in temperatures up to 320ºF. Nearly 235,000 ACH were shipped to US Army. MSA Safety Works was awarded Vendor of Year from True Value. New Safe Escape Respirator gets first NIOSH CBRN approval for escape respirators. ForceField Body Armor product line was introduced at International Chiefs of Police show in Miami Beach. 2006 MSA acquired Paraclete Armor and Equipment. Safety Products and Instrument Divisions were combined and became MSA North America. Murrysville plant received OSHA VPP award. Awarded $36M Air Force contract for new FireHawk® Defender SCBA, that combines APR, SAR, and SCBA into one unit. Defender Visor, integrated eye protection within Cairns Fire Helmet was major hit at Fire Rescue show. Altair Single-Gas detector line was launched. Evolution 5200HD2 TIC used a new camera core to achieve even higher picture resolution. The Workman fall protection line was introduced, primarily for construction. 2007 Bill Lambert was elected Chief Operating Officer. Cairns Helmet production shifts to Jacksonville. FireHawk® M7 SCBA was first to be certified as meeting the new NFPA standard for Breathing Apparatus and Personal Alert Safety System (PASS) devices. Fall Protection Harnesses and Lanyards were redesigned to meet new CSA standards. Developed jointly in Europe and NA, the first new design since early 1990s, the OptimAir TL Powered Air-Purifying Respirator (PAPR) was launched. The Altair 5 joined the Altair 4. The Chilgard M-100, AirGo Modular SCBA, and the Fuego Fire Helmet launched in Europe. MSA received the Outstanding Corporate Innovator Award from The Product Development and Management Association. 2008 Sales reached record $1.13 billion. MSA Suzhou, China R&D facility opened. MSA Italy and Germany celebrated 50th anniversaries. John T. Ryan III retired in June after 17 years as CEO, continues as Chairman of the Board. Bill Lambert was elected CEO. MSA awarded a $29 million contract with the US Army for Advanced Combat Helmets. $25 million additional in USAF FireHawk® M7 Responder Air Mask contracts. MSA received 2007 Pittsburgh Business Ethics Award. Cranberry, PA, manufacturing plant received the OSHA designation as national Voluntary Protection Program Star Site. Altair® 4 Detector was selected as MSA Product of the Year. 2009 FireHawk® M7 Responder SCBA was selected as MSA Product of the Year. Sales included $45 million in US military contracts for Advanced Combat Helmets, $10 million in M7 Responder Air Masks USAF contracts, $4.5 million in FireHawk® M7 Responder Air Masks to USCG, and $5.6 million in SCBA sales to Hong Kong Fire Department. Advantage® 400 Respirator was released with global approval. European Hard Hat Strategy implemented to expand market share of MSA flagship brand. New brand positioning of “MSA—The Safety Company” is adopted globally by all affiliates.

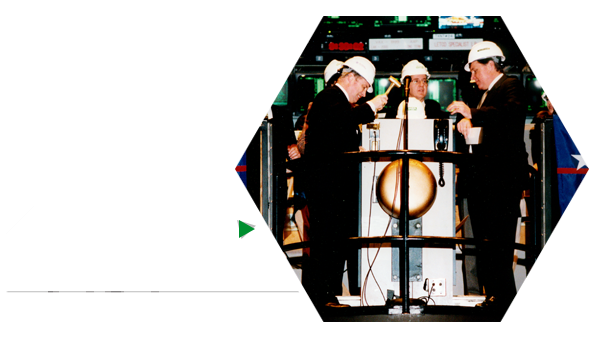

2000

Ding, Ding, Ding – MSA Hit the Stock Exchange

On June 14, John Ryan along with most of the Executive Team, rang the bell to begin trading on the American Stock Exchange with a 3-for-1 stock split in mid-year.

2001

9/11

In response to terrorist attacks of 9/11, MSA assistance at Ground Zero in NYC included:

- • Fit-testing trailer and personnel

- • Three tractor-trailers of product shipped within six hours

- • Round the clock representation on-site

- • $200,000+ donated

2000

FDNY Selected the Evolution® 4000 TIC

The innovative MSA Evolution® 4000 Thermal Imaging Camera (TIC) was introduced with the largest, highest resolution screen for ease of use. TICs use infrared light to give firefighters the ability to see through a dark, smoke-filled environment, to find the seat of a fire, or victims hiding or trapped. Many have been rescued through the use of Evolution TICs.

2004

FireHawk® Air Mask

The FireHawk® Air Mask was the first SCBA to meet new firefighting performance standards, as developed by the National Fire Protection Association (NFPA). At launch, this mask was the most ergonomic, comfortable SCBA available. It included an integrated Rescue belt that allowed emergency egress from upper floors.

-

2010

Largest Acquisition

MORE INFO

2010

Advancement in Gas Detection

MORE INFO

2011

MSA + GM = New Products

MORE INFO

2012

V-Gard Enhancements

MORE INFO

2010 — 2019 A decade of MSA in review:

2010 XCell® Sensor Platform for ALTAIR 4X Detectors launched successfully and was named Product of the Year. EVOTECH® Harness, AirXpress™ Breathing Apparatus and Prima®X Fixed Gas Detection System were also launched. MSA was selected by International Association of Fire Fighters as exclusive development partner for design of next-generation firefighting SCBA, known internally as the low-profile apparatus. Several hundred associates moved to remodeled Cranberry Township corporate campus, saving $3 million annually. 2011 MSA achieved highest annual net sales in its history at $1.2 billion. Income from Asia Pacific Zone increased by 400%. Four new offices opened in Russia to serve needs of its oil and gas workers. The new Altair 5X Detector greatly increased sales over previous generation Altair 5 Detector. Additional new product launch included SUPREMA® Touch Controller for fixed gas detection systems, PrimaX IR Gas Monitor infrared fixed gas detection system, the Workman Twin Leg Personal Fall Limiter, and expansion of flagship V-Gard Helmet line to include selection of accessories. MSA and General Monitors launched six cross-branded product platforms including GM PA4000/MSA Chemgard® Monitor and Flamegard® 5 Flame Detection System. Ballistic vest product group was divested. MSA was selected as SCBA supplier for the Pittsburgh Bureau of Fire (PBF). 2012 2012 was the most profitable year in MSA history; core products sales comprise two-thirds of $1.2 billion in sales, with net income growth at 30% from 2011. MSA established new Engineering Center of Excellence in São Paulo, Brazil GALAXY® GX2 Automated Test System launched successfully; V-Gard Accessory System and Ultrasonic™ Ex-5 Detector launched in Europe. SUPREMATouch® Modular Fire and Gas Detection System launched in China. Europe 2.0 initiative launched to adopt standardized pan-European business processes via new common IT platform and facilities consolidation. MSA Mexico celebrated 55 years; MSA Australia celebrated 50 years and MSA Gallet in Châtillon-sur-Chalaronne, France celebrated its first decade. Newly rebranded Website-MSASafety.com – went live. MSA CEO Bill Lambert was named Ernst and Young Entrepreneur Of The Year® (manufacturing category) for Western Pennsylvania and West Virginia. 2013 Significant new product introductions included the V-Gard GREEN Helmet, made from renewable sugarcane; FireHawk® M7XT Air Mask designed to meet the latest NFPA standard for Breathing Apparatus and Personal Alert Safety Systems (PASS); Gasgard100 Controller; Horizontal Lifeline Bypass Shuttles; Z-Gard Upgrades; and the latest generation TIC that conformed to new NFPA standard for Thermal Imaging Cameras – Evolution® 6000 Series. Chilean Fire Bureau purchased another round of FireHawk® M7 SCBA.

2010

Largest Acquisition

On October 13, MSA made the largest expansion in its history with the acquisition of General Monitors of Lake Forest, California. This union created the world leader in fixed gas and flame detection.

2010

Advancement in Gas Detection

The most technologically advanced gas detection available, the XCell® Sensor Platform for ALTAIR® 4X Detectors, launched.

2011

MSA + GM = New Products

MSA and General Monitors launched six cross-branded product platforms including GM PA4000/MSA Chemgard® Monitor and Flamegard® 5 Flame Detection System.

-

Conclusion

In the decades that have come and gone, our products have expanded beyond mine safety and so has our name.

We started out as Mine Safety Appliances Company in 1914, and have evolved to be known today as MSA: The Safety Company, which better reflects our on-going mission to lead the world in the development and production of products and systems to protect people and property.

Although some things have changed, our purpose hasn't, and never will. We're still the only company in the world solely dedicated to keeping people safe.

There is no content for this item available at this time.